Our production

LLC "Promplast" company is engaged in the production of peripheral equipment for extrusion blow molding machines.

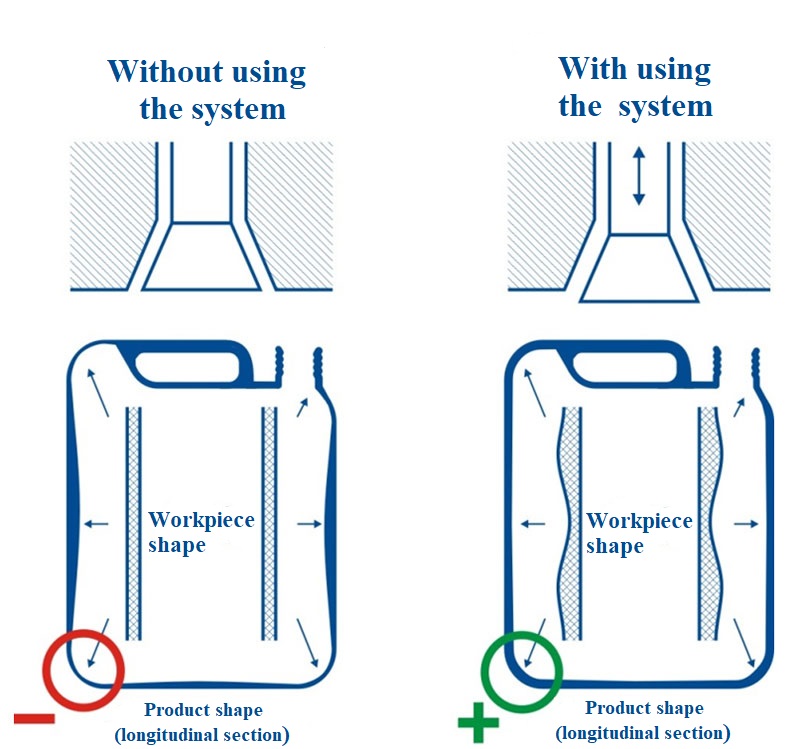

One such systems is SSPC (Servo Driven Parison Control System). It is used in the formation of a workpiece with a complex multi-thickness multi-stage structure and allows you to optimize the mass of material along the wall of the product, such as a canister.

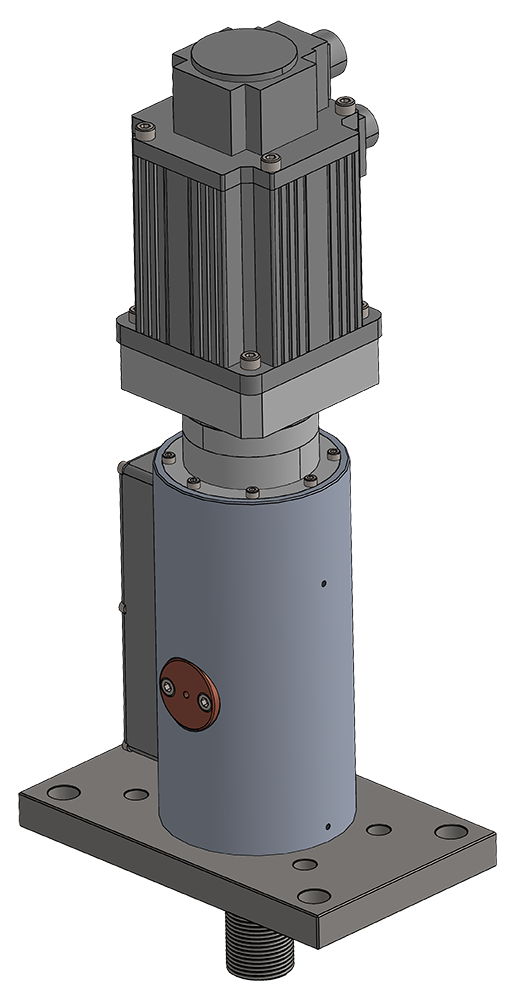

The main difference from other similar systems, such as MOOG, is that the SSPC does not use hydraulics. Thanks to this, it is possible to significantly save on the energy consumption of the hydrostation, at least by 40-50 percent, which can significantly reduce the cost of the product in the production process.

We are the largest manufacturer of polyethylene containers in the North-West of Russia. Among the company's customers are the largest enterprises in the chemical, food and perfume industries: «Henkel», «Nordix», «Tekomkhim», «Aquaphor», «Suprotec», «Khimpromproekt», «Pskovnefteprodukt», «Dolphin», «Khimik», «Gardener's Green Pharmacy», «NitroSibirZapolyarye», «Baochemi», «VMP-Auto», Evrotek», «Lenbytkhim».

We are open for cooperation with any countries. Contact us and tell you more about our product.

Specifications

| Model | SSPC-01 | SSPC-02 | |

| Product dimensions | [mm] | 865*275*170 | 670*275*170 |

| Weight | [kg] | 74,1 | 31,0 |

| Max. force on the stem | [N] | 85000 | 35000 |

| Max. stem speed | [mm/s] | 25 | 25 |

| Stroke length of the stem | [mm] | 6,25 / 12,5 at the request of the customer | 6,25 / 12,5 at the request of the customer |

| Rod movement stem | [mm] | 0,05 | 0,05 |

| Number of points on the graph | [pcs] | from 10 to 256 | from 10 to 256 |

| Supply voltage | [Volts] | 3 phase-380/1 phase-220 | 3 phase-380/1 phase-220 |

| Operating temperature | [°C] | -10 to +70 | -10 to +70 |

| Protection class | IP44 | IP44 |

Product description

The servo-driven parison control system for extrusion blow molding machines SSPC is designed to adjust the wall thickness of the workpiece by changing the gap between the movable and stationary forming element of the extrusion blow molding machine head.

SSPC is designed for operation in S1 mode (according to GOST R 52776-2007) with continuous operation in a non-aggressive, non-explosive environment with a content of non-conductive dust up to 10 mg/m3.

Acquisition Benefits

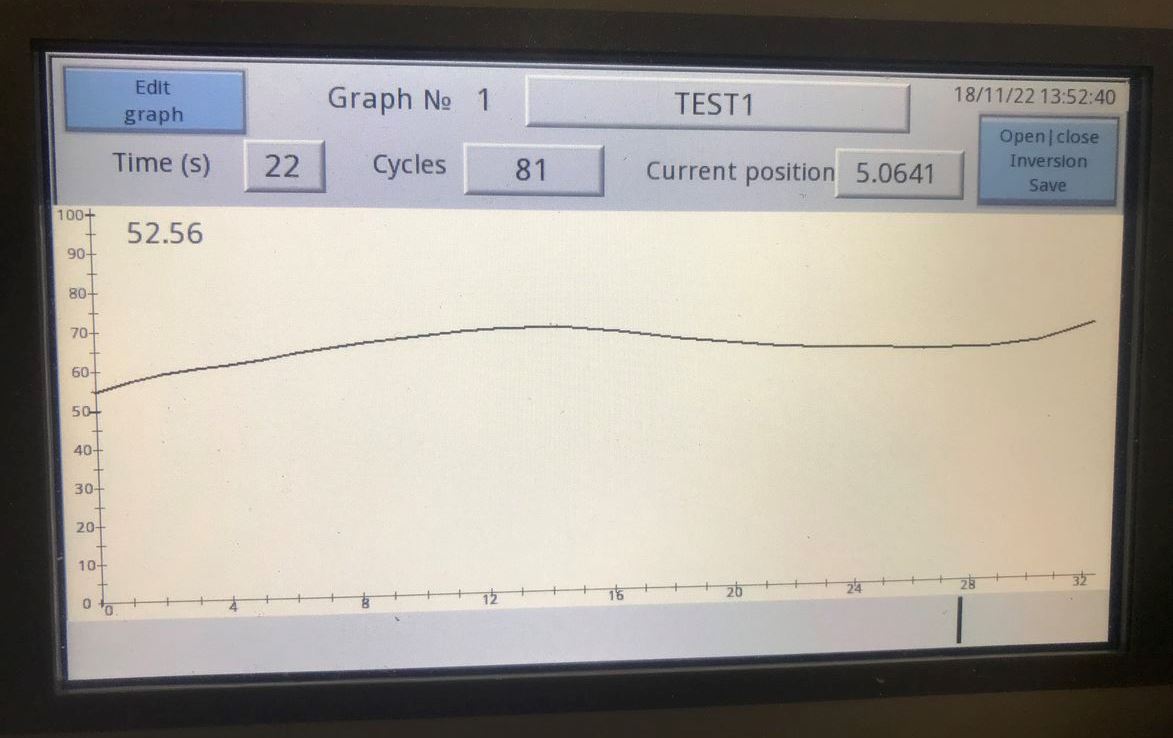

How the system works

When setting up a continuous extrusion machine, a time-based program is used. The signal for the beginning of the program cycle sequence is received from the machine (cutting off the workpiece or signal from the photo sensor ), which is also the signal for the end of the previous program cycle. SSPC measures in each cycle the time interval between two successive slices of the workpiece and distributes the values set from the control panel in the measured time interval at equal intervals . The duration of the intervals for the execution of the program for changing the thickness is determined by the duration of the product manufacturing cycle.